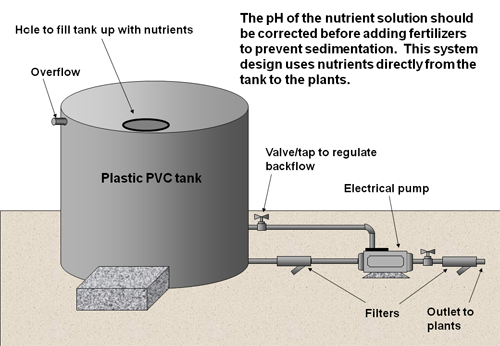

Nutrient tank design with pumps and filters

Bag culture systems requires the use of large tanks to store the nutrient mixture. The tanks are important because:

- The nutrients are mixed and stored in the tanks

- The exact amount of nutrients can be added to a specific volume of water since the size of the tank is known.

- The exact amount of water can be applied to the plants

- The size of the tank will be determined by

- The type of crop grown

- The area under cultivation

- The type of hydroponic system that will be used

- The degree of automation required

Nutrient tanks must be either plastic or should be painted with BUTAMIN on the inside. This is important since the nutrient mix will react with materials such as iron, aluminium, copper, concrete etc. Galvanized tanks will cause Zn toxicity within a few months of operation.

The components of a nutrient tank are shown in the figure below. Each tank should have a hole in the top so that fertilizers can be added with relative ease. Since the tanks are at least 1m high; lifting a 20kg bag or 20L water can become tiresome.

The size of a nutrient tank will be determined by how many plants need to be irrigated, the water consumption per plant per day, the degree of automation and layout of the overall system. The minimum requirement is to start with at least 2 L.plant-1 day-1. So if there are 1000 plants in the system one would use 2000L.day-1. It also implies that the nutrient tanks must be filled with nutrients and water at the end of each day for 365 days a year. This might become a problem during holidays. If a 10,000L tank is installed, nutrients and water need only be added once in every five days. Ideally one would design an irrigation system that has the capability of delivering 3L.plant-1 day-1.

Share This Story, Choose Your Platform!

Cotton aphid – Aphis gossypii

Cotton Aphid, or Aphis gossypii, is one of the more common insect pests found in almost all vegetable crops and [...]

Greenhouse white fly

Description Greenhouse white fly, also known as Trialeurodes vaporariorum is a sap feeder. The easiest way to find white flies [...]